State of the art equipment combined with highly skilled personnel and a commitment to exceed expectations make Trutron a valuable partner capable of meeting customer needs. Our ability to work with customer’s engineering, manufacturing and quality departments is highly regarded and make Trutron a valuable addition to your problem solving team.

CNC Jig Grinding

Complex cam contours and elliptical shapes are ground with CNC Continuous Path Jig Grinders. 5-axis grinding is achieved with an integrated rotary table holding tight profile and finish tolerances.

CNC Turning

CNC Turning Centers allows us to machine a wide variety of materials ranging from aluminum to tool steels to super alloys. Hard turning 64 Rockwell tool steels with close tolerance shapes and surface finishes is a common practice.

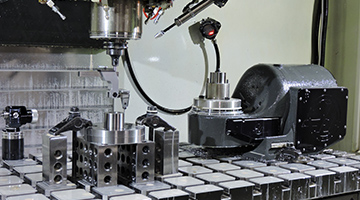

CNC Milling

In addition to 3 and 4-axis milling, we have full 5-axis simultaneous milling capabilities that minimize fixture costs and reduce set-up time. The result is faster throughput and a more precise product.

5-Axis CNC Machining

High speed contouring machines featuring spindle speeds of 42,000 rpm and 1G acceleration/deceleration allows machining of hardened tool steels up to 64 Rockwell while holding critical tolerances on complex geometries.

Sinker EDM

Sinker EDM equipment, combined with years of operator experience, assist in the creation of parts / tools with complex geometries holding tolerances of +/- .002.

Wire EDM

Wire EDM equipment is capable of machining complex precision parts with dimensional tolerances within +/- .0005 and 4-axis shapes with a maximum taper angle of 30 degrees at 4 inches.

CNC EDM Hole Drilling

EDM hole drilling equipment provide the capability to drill blind and through holes ranging in size from .020 to .120 diameter with reliable dimensional accuracy and fine finishes.

Inspection

The ability to accurately and efficiently dimensionally inspect components with exceptional precision is made possible by utilizing specialized gaging in conjunction with state of the art equipment like our Zeiss Coordinate Measuring (CMM) and Visual Instant Measurement Machines. We have the ability to dimensionally inspect within a millionth of an inch and flatness as close as one helium light band. The inspection Department is capable of providing data in any format required. First Article Inspections are performed to the AS9102 Industry standard.

Benching

Finely skilled bench hands ensure customer specifications are met including critical deburr, blending, surface finish, and polishing requirements. Experienced bench hands routinely hand polish with accuracy within .0001.

ID/OD & Surface Grinding

Precision grinding capabilities including OD Grinding, ID Grinding, and Surface Grinding are available to complement other machining requirements. Highly skilled operators familiar with a variety of materials reliably meet customers’ exacting specifications.

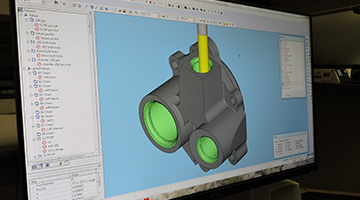

CAD/CAM

Our engineering department has the ability to work from 2D prints or directly from customers’ AutoCAD or SolidWorks files. We accept CAD data in almost any format and are extremely proficient with 3D solid modeling, parametric modeling and surface data generation. Esprit software is utilized for machine programming.

Hone and Lap

Combining years of experience and state-of-the-art flat lapping equipment, allow us to hold flatness tolerances of up to 2 helium light bands. With our high precision ID honing equipment, we are able to maintain diameter tolerances as close as .0001 keeping roundness as little as .00004 (Inches) total deviation.